| Introduction of reducer test bench (click to enter) |

| Hits:9630 AddTime:2021/9/20 21:19:35 |

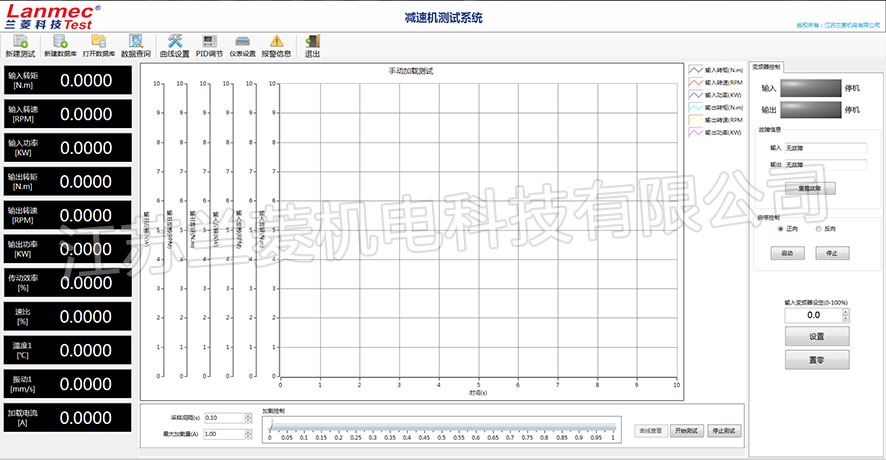

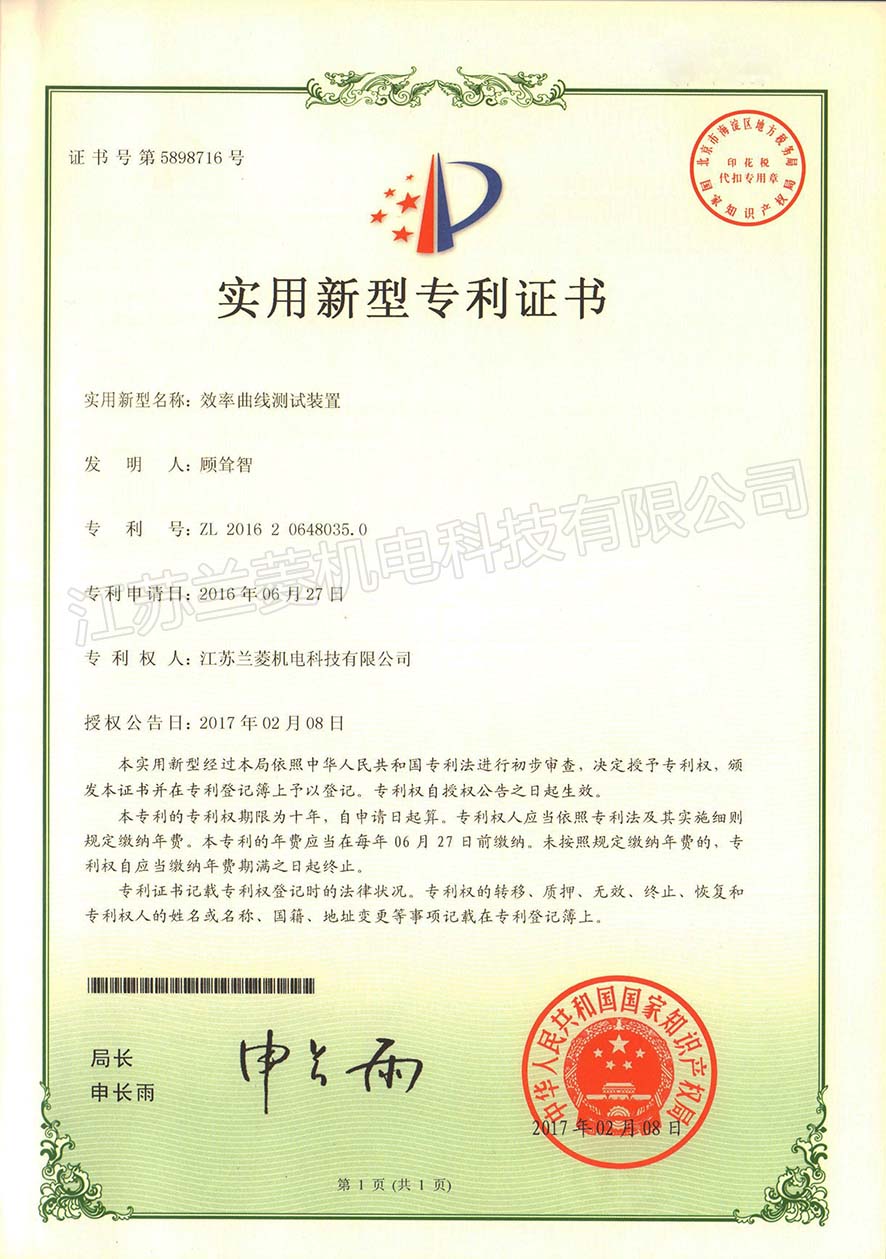

Equipment Name: Reducer Test Bench Equipment introduction: The reducer test bench is to study the transmission performance of various gear transmissions, belt transmissions and continuously variable transmissions. Important equipment for evaluating product quality. Through the test, the rationality of the design of the transmission device, the manufacturability of processing, manufacturing, assembly and debugging can be checked. The in-depth analysis of the test results will help to understand and evaluate the comprehensive mechanical properties of the transmission components and devices, and also provide practical reference materials and design basis for engineering designers. Measurement parameters: input torque, speed and power of the reducer; Output torque, speed, power; Conversion efficiency Vibration, noise, temperature rise, etc. Measurement accuracy: torque, speed, power, reducer efficiency ±0.2%F.S Temperature ±0.2℃ Loading method: magnetic powder brake loading, hysteresis brake loading, eddy current brake loading, power feedback loading Installation method: The large bottom plate adopts HT200 cast iron platform (return processing), and the surface is ground to ensure that the flatness is less than 0.05mm. Install shock absorbing pad and level adjustment horn under the platform; The reducer under test is installed on the sliding platform separately, which can be moved forward and backward and locked separately, which is convenient for installing the reducer; ensure the installation concentricity ≤0.03mm Coupling: the use of elastic pin (diaphragm, plum, pin) type coupling. The reducer under test is installed on the sliding platform through a bracket, using the same mounting bracket, and different flanges and couplings are replaced for different models. The specific structure is communicated by both parties, and the drawings determined by both parties shall prevail Software function: It is used to test various parameters of servo motor, drive and planetary reducer. Various parameters can be displayed, stored and printed by computer and instrument; and the curve relationship between each parameter can be displayed, stored and printed Can be loaded manually, program-controlled loading; program control of the speed, time, etc. of the active motor Final acceptance After the equipment has been commissioned on site by Party A, both parties will conduct final acceptance of the machinery, electrical and software of the equipment. After passing the test, both parties will sign and confirm, and the unqualified items will continue to be rectified until they are qualified. After-sales service Within 12 months after the acceptance of the dynamometer (the torque and speed sensor is 24 months), if all components and instruments fail (Non-artificial) Three guarantees will be implemented. The courier replacement that can be replaced by courier, and the phone can be resolved by phone. If it cannot be solved, Party B must arrive at the site of use within 24 hours. For equipment failures caused by reasons other than Party B, material costs, road expenses, and labor hours will be charged at cost. After 12 months, Party B will arrive at the site to use the paid service within 24 hours. Commissioning training After receiving the call from Party A to request debugging, Party B must arrive at the demand site within 48 hours, and the debugging is completed within 3 days. During this period, the operator can be trained free of charge. |

| 【Refresh】【Favorites】【Print】 【Close】 |

| Previous:Planetary reducer test bench Next:Traction machine test bench (click to enter) |

- Torque speed sensor

- torque speed sensor

- Magnetic powder clutch

- Magnetic powder brake

- Tension control system

- Deviation control system

- Safety chuck

- Air shaft

- Eddy current brake

- Hysteresis brake

- Hysteresis clutch

- Hysteresis dynamometer

- Eddy current dynamometer

- Magnetic powder dynamometer

- Electric dynamometer

- Chassis dynamometer

- Hydraulic dynamometer

- Engine, axle, gearbox, PTO test bench

- Motor test bench

- Reducer test bench

- Actuator, worm gear box, test bench

- RV, Harmonic and Planetary Test Bench

- Traction machine test bench

- Drill pipe test bench

- Hydraulic wrench test bench

- Slewing bearing test bench

- Hydraulic pneumatic motor test bench

- New energy vehicle transmission test bench

- Non-standard custom test bench

- Acquisition instrument

- Testing software