| Magnetic powder brake-total profile |

| Hits:28728 AddTime:2023/7/22 8:17:55 |

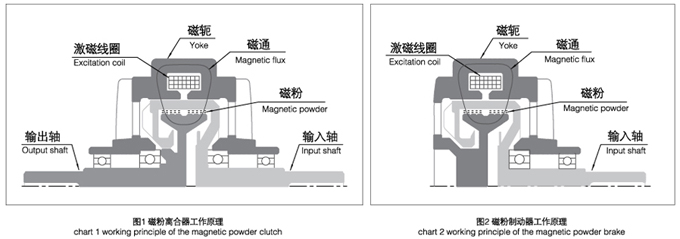

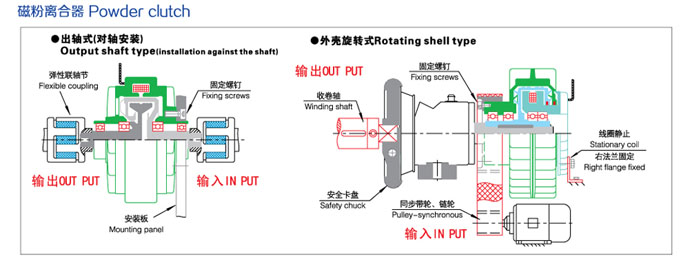

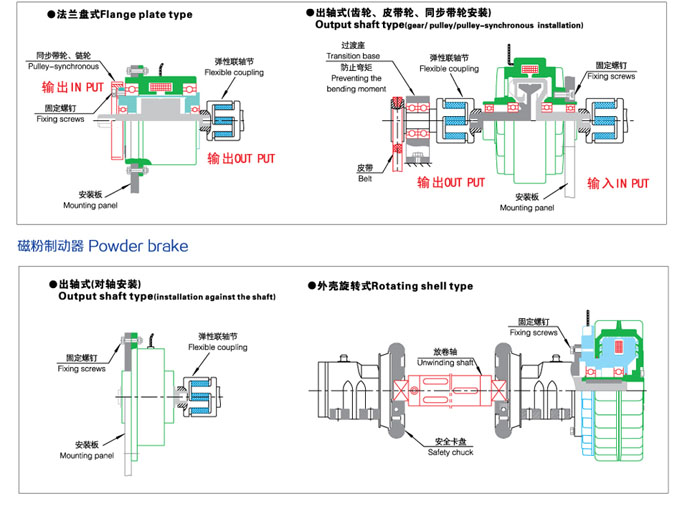

| The structure and working principle Magnetic powder clutch is (input shaft), driven by the active rotor rotor (output shaft), including excitation coil of the magnetic yoke of relative concentric three parts assembly, can form a relative rotation of the whole, in the annular space between the driving rotor and driven rotor cavity (work) filled with high magnetic conductivity alloy magnetic powder. Excitation, and current through the coil, the working cavity of magnetic powder in loose state.In under the action of centrifugal force generated by the active rotor and magnetic powder is evenly in the active rotor on the inner wall of weak interaction between the main rotor, driven, magnetic powder clutch in the separation of state, not the transmission of torque. Excitation coil is energized, the yoke of magnetic flux, the magnetic powder in working cavity along the direction of the magnetic flux linked in chain (form a chain of magnetic powder), magnetic powder clutch is depend on the magnetic powder and magnetic powder, and the working surface between friction and magnetic powder chain between the shear resistance to transfer torque, magnetic powder clutch in the combined state.(see figure 1) Cut off the current, flux disappear, with the disappearance of the exciting current of magnetic powder under the action of gravity, in a loose state again, and under the action of centrifugal force, was in active rotor on the inner wall of magnetic powder clutch and is in a state of separation. The principle of magnetic powder brake and magnetic powder clutch is the same, as long as the magnetic powder clutch driven rotor fixed, magnetic powder brake was created.

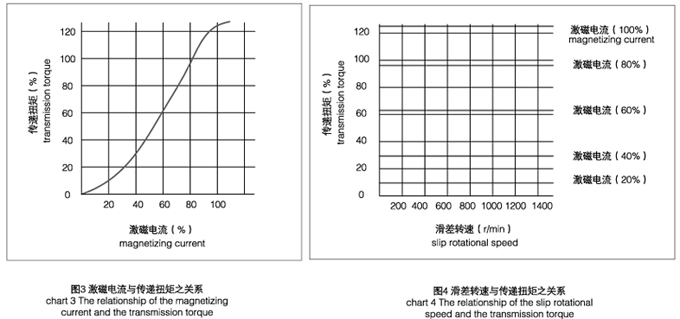

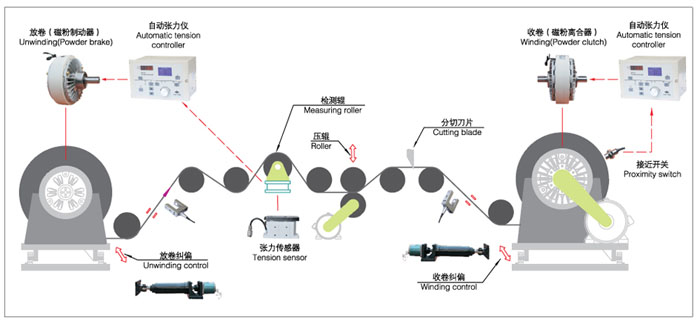

features The excitation current and torque is linear relationship As shown in figure 3, transfer torque and excitation current of a linear relationship with basic.As long as you change the size of the excitation current, can control the size of the torque on a wide range.Normally within the scope of 5% to 100% of the rated torque, exciting current and the transmission torque directly proportional basic linear relationship. The stability of sliding structure moment When the excitation current is kept constant, the transmission of torque is not affected by active speed difference between a follower (slip speed), as shown in figure 4.That is to say, there was no difference in the static friction torque and friction torque, thus to achieve stable torque constant.This feature is applied to tension control, the user as long as the excitation current can accurately control the torque, so as to effectively control the tension of coil. Prevent due to slip of fever Usually continuous sliding friction parts will be fever, and even burn out.But this equipment has the complete radiator, long time operation is not too hot, and long service life.

In addition, magnetic powder clutch can also be used to buffer starting, overload protection, control, etc.;Magnetic powder brake can also be used for mechanical transmission test load, brake, etc.

|

| 【Refresh】【Favorites】【Print】 【Close】 |

| Previous:FKG-AN micro magnetic power clutch Next:FZ-AK magnetic power brake |

- Torque speed sensor

- torque speed sensor

- Magnetic powder clutch

- Magnetic powder brake

- Tension control system

- Deviation control system

- Safety chuck

- Air shaft

- Eddy current brake

- Hysteresis brake

- Hysteresis clutch

- Hysteresis dynamometer

- Eddy current dynamometer

- Electric dynamometer

- Magnetic powder dynamometer

- Hydraulic dynamometer

- Chassis dynamometer

- Drill pipe test bench

- Actuator, worm gear box, test bench

- Engine, axle, gearbox, PTO test bench

- Reducer test bench

- Traction machine test bench

- Motor test bench

- RV, Harmonic and Planetary Test Bench

- Hydraulic pneumatic motor test bench

- Hydraulic wrench test bench

- Testing software

- Slewing bearing test bench

- Acquisition instrument

- New energy vehicle transmission test bench

- Non-standard custom test bench

- High and low temperature test chamber

- coupling

- Industrial chiller